“Time lost is productivity lost.”

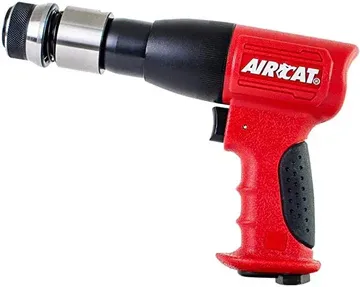

Tire changes are one of the most common tasks in a service garage. But slow equipment or poor technique can waste valuable time. That’s why many shops begin with a large air hammer, known for removing stubborn lug nuts quickly. Using the right air-powered tools at the start of the process cuts delays and speeds up workflow.

Every minute a vehicle is off the road means lost revenue. Delays during tire swaps are usually caused by equipment problems or poor planning. Improving speed doesn’t require cutting corners. It starts with being smart about your setup, tools, and training.

1. Pre-Check Before You Start Saves Time Later

One small delay early in the process can snowball into major downtime. Always check your air pressure, tire size, and tread wear before touching the tire. Lay out your tools in advance, especially the large air hammer, sockets, and alignment devices. This small step prevents walking back and forth and avoids repeated setup delays.

2. Use the Right Size Air Hammer for the Job

A large air hammer gives more impact force than smaller ones. That means it works faster on rusted or over-tightened lug nuts. Using one correctly avoids wasted time and physical strain. A lightweight tool can lead to stripped threads or broken studs. So, match the hammer to the task to keep everything running smoothly.

3. Tire Bead Breaking Needs Speed and Safety

Breaking the bead, the tire’s seal with the rim—can slow the process down. Manual bead breakers may get the job done, but they’re slower and harder to control. Machines with assist arms or powerful bead breakers reduce the time and effort needed. Look for units that don’t require frequent resets or multiple passes.

4. Lift Systems Reduce Physical Strain and Errors

Lifting heavy wheels manually not only causes fatigue but can lead to improper alignment. Mechanical lifts reduce the risk of errors during reinstallation. Less strain means technicians stay productive longer and avoid injuries. An efficient lift setup also helps speed up the final mounting and balancing stages.

5. Organize Tools for Speed and Flow

Keep your tire changing area clean and well-organized. Tools should be within arm’s reach. That includes your large air hammer, valve tools, patches, and balance weights. Floor clutter and tangled cords increase the risk of injury and slow things down. A clear space means faster, smoother motion between each step.

6. Routine Maintenance Prevents Unexpected Breakdowns

Machines that aren’t maintained well cause sudden failures. Regularly check your compressors, hoses, and tire changers. Look for worn-out seals, leaks, or faulty gauges. A five-minute inspection can save you hours of downtime later. Replace worn parts before they break, waiting until something fails is never worth the risk.

7. Training Matters More Than Speed Alone

Even the best equipment won't help if the operator is untrained. Short, regular training sessions can make every tire change faster and safer. Teach your team how to use all the machine features correctly, especially newer models. This builds consistency across shifts and reduces rework.

8. Final Mounting: Let the Machine Do the Work

Over-relying on manual effort slows down the tire mounting process. Use your changer's assist arms for hard sidewalls. Ensure proper tire lube is applied evenly to avoid resistance. Let the equipment guide the tire into place, reducing wear on both the tire and machine.

9. Corgi Equipment Speeds Up Every Step

If your shop handles frequent tire changes, upgrading to a corgi tire machine is a smart move. These machines are known for fast cycle times, ergonomic features, and consistent results. They reduce operator strain and increase accuracy like two major factors in cutting downtime.

Final Conclusions

Reducing tire change downtime isn’t about working faster, it’s about working smarter. Start with powerful tools like a large air hammer, follow a simple prep routine, and invest in reliable machines. A corgi tire machine brings lasting value by making tire swaps quick, safe, and repeatable. These small upgrades lead to better customer flow and stronger shop performance.